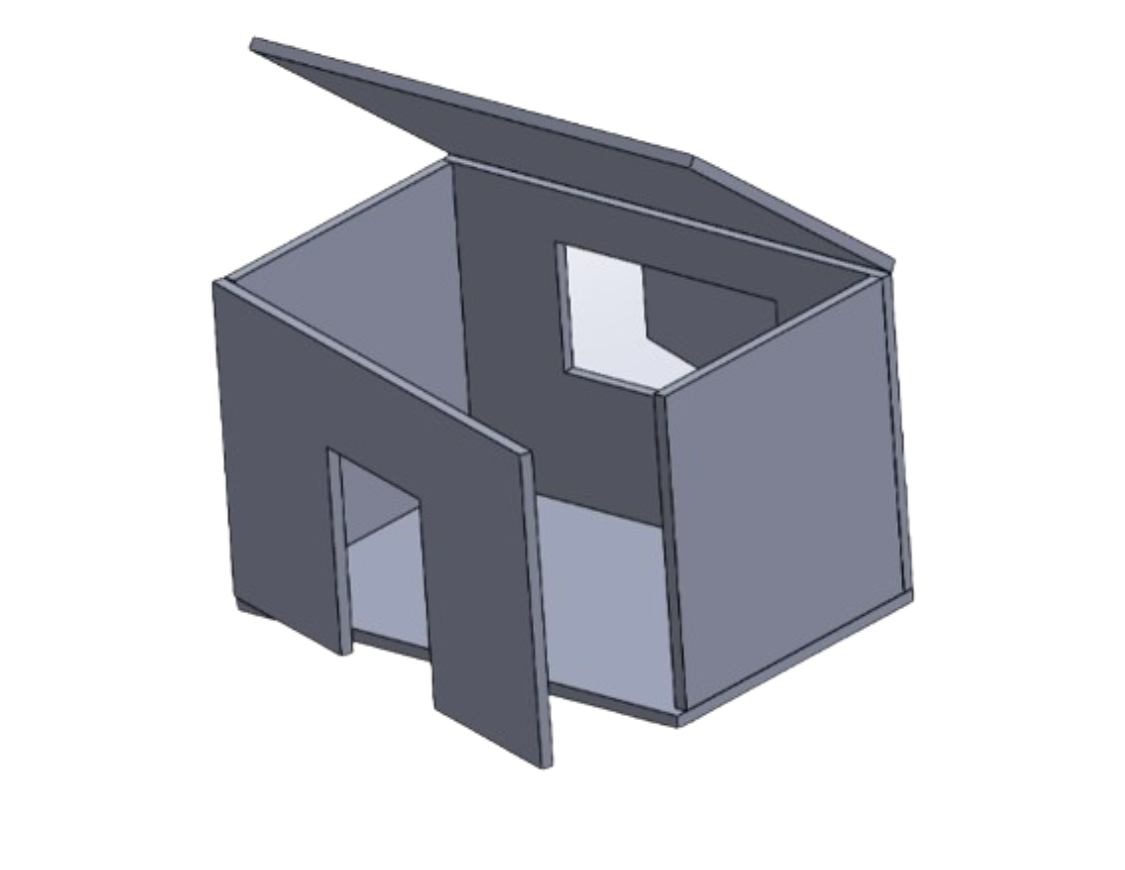

This CAD model illustrates the Brewista's exterior frame design, emphasizing functionality and accessibility. The top and front plates are hinged for easy access to components during installation and maintenance. Additionally, a back door provides access to electronics.

The frame is constructed from standard half-inch plywood. The side plates sit on top of the bottom plate, while the top plate rests on the side plates. This configuration ensures structural integrity and minimizes the weight for the screws securing the components.

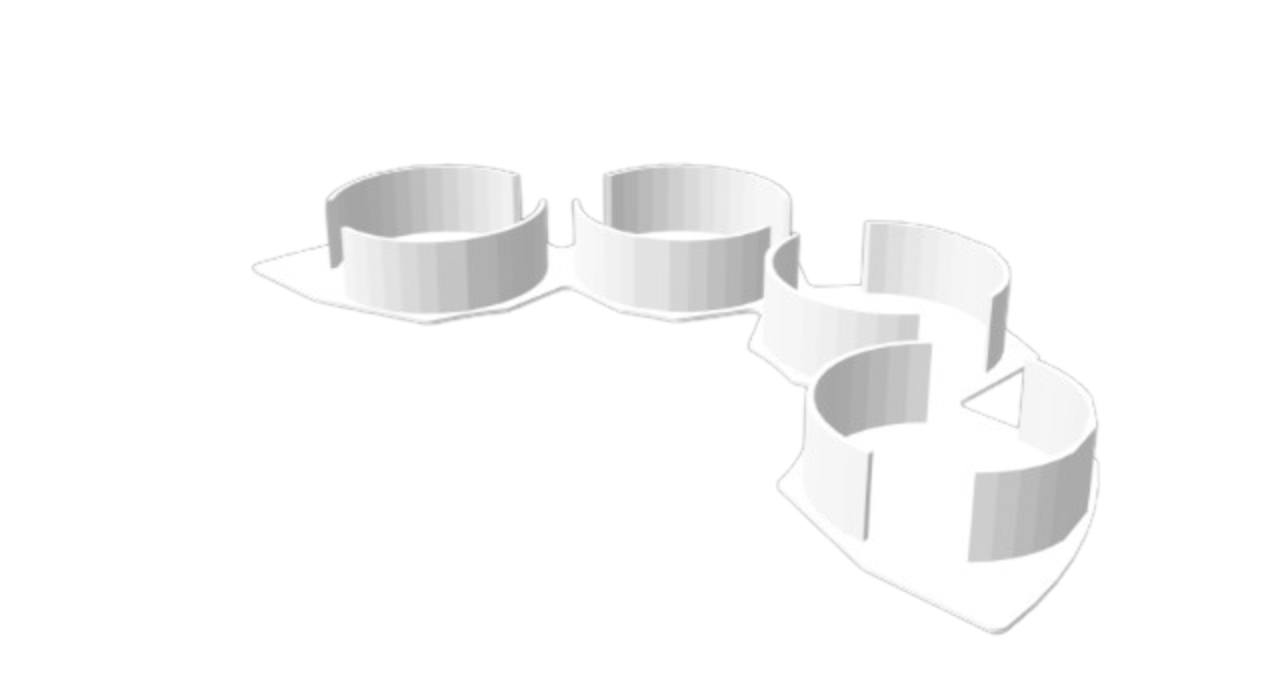

The cup holders underwent multiple revisions to reduce space and optimize print time. The final design features four holders for the reservoirs arranged in an arc, ensuring equal distance from the main filling area. The walls of the cup holders are two inches tall, slightly under half the height of the reservoirs.

The jagged pattern on the model's floor was initially a large rectangle covering the Brewista's entire floor space. However, this was inefficient. Consequently, the unnecessary space was removed, while retaining the corners at the tips of the "U" shape to ensure a snug fit in the Brewista's corners.

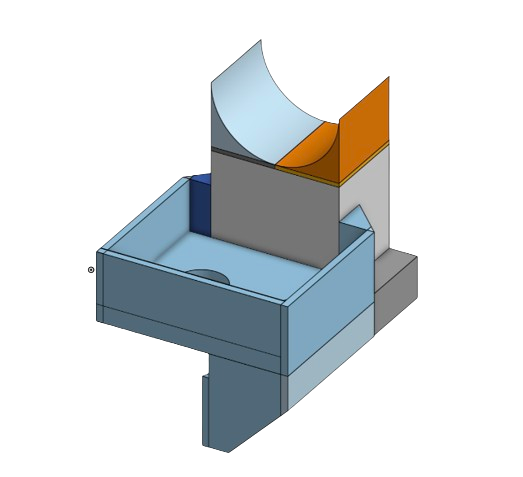

The mount is essential for securely positioning and aligning the peristaltic pumps, reservoirs, and electronics within the Brewista. It ensures efficient liquid transfer and system reliability.

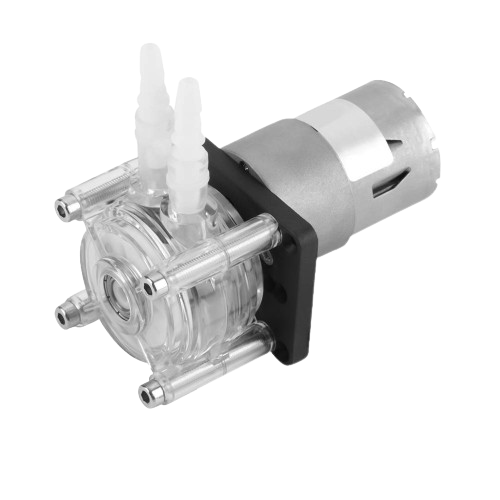

The peristaltic pump operates by squeezing liquid through its bearings from one side to the other. This squeezing action is achieved by rotating rollers along the tube, creating a vacuum effect that moves the liquid through the pump.

One side of the peristaltic pump is connected to the reservoir, where it draws the liquid from. The output spout of the pump then pours the liquid into the cup, allowing for a controlled and precise dispensing of liquids.